On December 6–8, 2017, the World Smart Manufacturing Conference took place at the Nanjing International Expo Center. The event, themed “Gathering, Blending, Creating, and Transforming,†brought together leading companies such as Gree Electric Appliances, China Railway Group, Huawei Technologies, Alibaba Cloud, and Despatch. These industry giants showcased their latest innovations in smart manufacturing, highlighting the growing importance of intelligent systems in modern production.

A central highlight of the conference was the main forum on December 7, where prominent figures from both government and industry shared insights on the future of smart manufacturing. Liu Lihua, Vice Minister of the Ministry of Industry and Information Technology, Zhou Ji, President of the Chinese Academy of Engineering, Dong Mingzhu, Chairman of Gree Electric Appliances, and Liu Hualong, Chairman of China Railway Group, discussed key topics such as the Internet of Things, big data, intelligent rail transportation, and supercomputing. Their discussions emphasized the need for innovation and technological advancement to drive the next phase of industrial growth.

Despite significant progress, China still faces challenges in the smart manufacturing sector. Many aspects of the industry lag behind global standards, not just due to a lack of first-mover advantage, but also because of limited creativity. Most smart manufacturing solutions today are still rooted in industrial automation, performing repetitive tasks based on pre-set instructions. While accurate, these systems often fail to engage users or inspire innovation.

For example, a robot that can play the keyboard may seem impressive at first, but its performance is essentially a programmed routine. The “novelty†comes from the presentation, not from the machine itself. This highlights a critical gap: while machines can be fast and efficient, they still lack true intelligence and adaptability.

As industries evolve, the role of machines is shifting. They are no longer just replacements for human labor; instead, they are becoming tools that support and enhance human capabilities. However, many of these technologies are imported, and their integration into local production processes remains incomplete.

Zhou Ji, Dean of the Chinese Academy of Engineering, stressed the importance of innovation. He called for a more proactive approach, leveraging advanced technologies like the internet, big data, and artificial intelligence to drive development. By focusing on high-end applications and accelerating research and implementation, China can overcome existing shortcomings and achieve a leap forward in manufacturing.

The new generation of intelligent manufacturing is moving beyond mere automation. It aims to create systems that can recognize, learn, and adapt—essentially making machines more like humans. This shift is already evident in projects like AlphaDog, which uses powerful algorithms and deep learning to handle complex tasks. As people transfer more cognitive work to information systems, the relationship between humans and machines is evolving from “giving fish†to “teaching how to fish.â€

While current robots may not match the intelligence of AI systems like AlphaDog, they are beginning to break free from the limitations of mechanical automation. The industry is gradually moving toward true intelligence, and this transformation is essential for long-term success.

Dong Mingzhu, Chairman of Gree Electric Appliances, emphasized the importance of innovation over imitation. With over 10,000 R&D personnel and multiple research institutes, Gree is investing heavily in technological breakthroughs. Only through real innovation can China’s manufacturing sector gain global recognition and make “Made in China†synonymous with quality and ingenuity.

In conclusion, as Liu Hualong, Chairman of China Motor Corporation, stated, “Strong manufacturing and equipment are the foundation of a strong country. Only through wisdom and innovation can we embrace the new era.†The future of smart manufacturing lies not just in machines, but in the intelligence and creativity that drive them. Intelligent Manufacturing? Yes, but what we truly need is intelligence—and more importantly, intellectualism.

Innovative Construction: Equipped with imported pocket-type PE separators, our batteries effectively prevent short circuits due to active material shedding, resulting in low internal resistance and high current discharge.

Advanced Safety Features: Special anti-acid explosion-proof patches are employed to isolate potential sparks, making our batteries safer for everyday use.

Patented Technology: The patented deep cycle positive paste and negative lead carbon technology significantly extends the battery's cycle life.

Efficient Design: Unique labyrinthine cap design allows for smooth electrolyte recirculation, minimizing water wastage and prolonging battery life.

Cutting-edge TTP Welding: Advanced TTP welding technology ensures minimal internal resistance during connections.

Special Valve Design: Prevents corrosion, enhancing the battery's durability.

High Assembly Pressure: This design feature significantly extends the battery's lifespan.

Wide Temperature Range: Our batteries are functional in temperatures ranging from -30°C (-22°F) to 70°C (158°F), accommodating diverse environmental conditions.

OREMA QTF series AGM automotive batteries introduce innovative technology, showing excellent instantaneous high current release performance, and its continuous casting grid technology enhances the corrosion resistance of the grid; By improving the mechanical strength of the grid, the anti-shock performance of the battery is improved.

The OREMA QTF Series AGM Automotive Battery is known for its powerful starting power, low water loss and long service life, and is specially built for vehicles requiring basic electric support. While maintaining superior performance, it provides a higher price/performance ratio. OREMA QTF Series AGM automotive batteries are designed to simplify life and add value to your car by providing more affordable and responsive battery solutions from the consumer's perspective.

Choose OREMA car batteries, which are prized for their long-lasting performance. Quality products can withstand the test of time and user inspection.

OREMA QTF series AGM start-stop batteries are at the forefront of lead-carbon technology, tailored for vehicles with start/stop and mild hybrid systems. Ideal for caravans, boats, motorhomes, and more, these batteries showcase exceptional charge acceptance and cold starting capabilities. Experience the difference with OREMA's advanced lead alloy formula, specifically designed for today's demanding automotive applications.

Key Features of OREMA 12V AGM car batteries:

Enhanced Durability: Crafted with reinforced design, the battery casing and cover are made of high-strength, heat-resistant PP engineering plastic, ensuring longevity and reliability under various conditions.Innovative Construction: Equipped with imported pocket-type PE separators, our batteries effectively prevent short circuits due to active material shedding, resulting in low internal resistance and high current discharge.

Advanced Safety Features: Special anti-acid explosion-proof patches are employed to isolate potential sparks, making our batteries safer for everyday use.

Patented Technology: The patented deep cycle positive paste and negative lead carbon technology significantly extends the battery's cycle life.

Efficient Design: Unique labyrinthine cap design allows for smooth electrolyte recirculation, minimizing water wastage and prolonging battery life.

Cutting-edge TTP Welding: Advanced TTP welding technology ensures minimal internal resistance during connections.

Special Valve Design: Prevents corrosion, enhancing the battery's durability.

High Assembly Pressure: This design feature significantly extends the battery's lifespan.

Wide Temperature Range: Our batteries are functional in temperatures ranging from -30°C (-22°F) to 70°C (158°F), accommodating diverse environmental conditions.

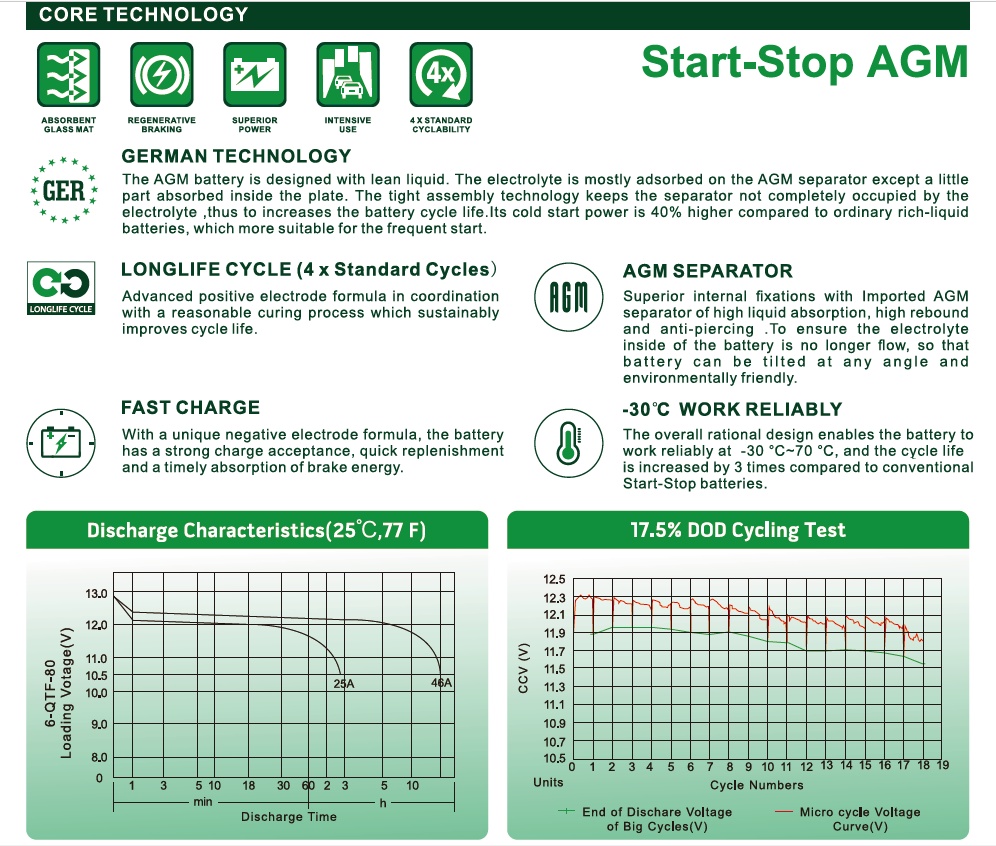

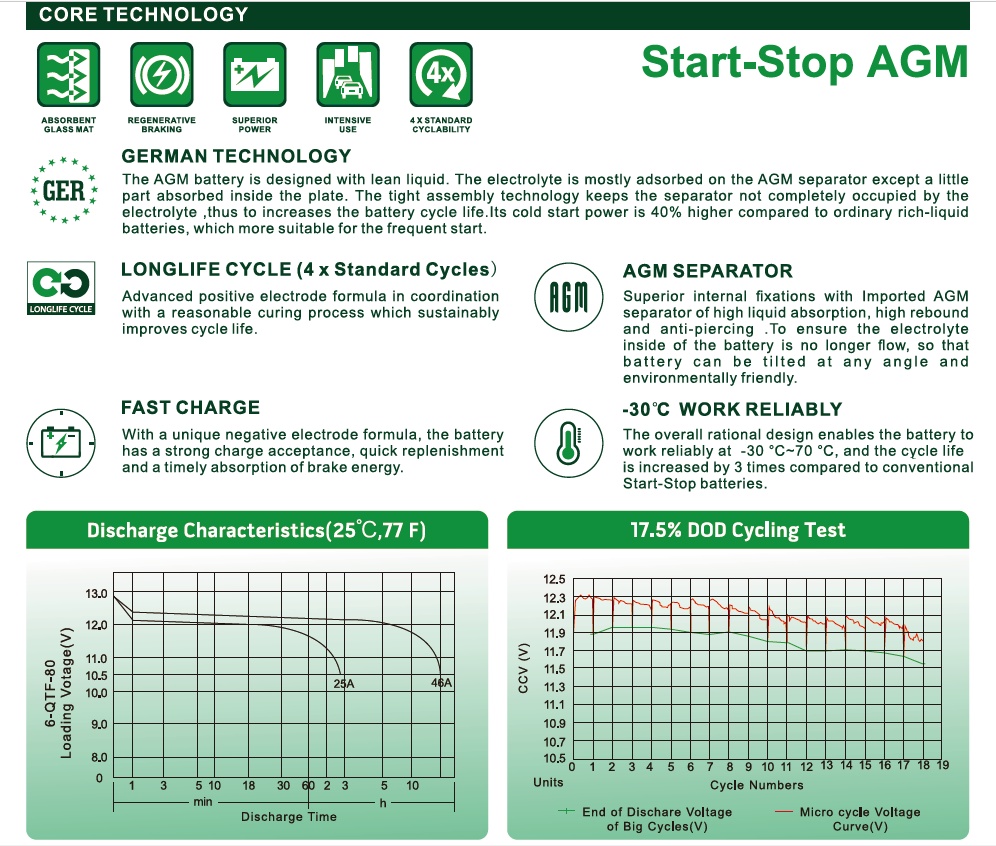

OREMA AGM car start-stop battery core technology:

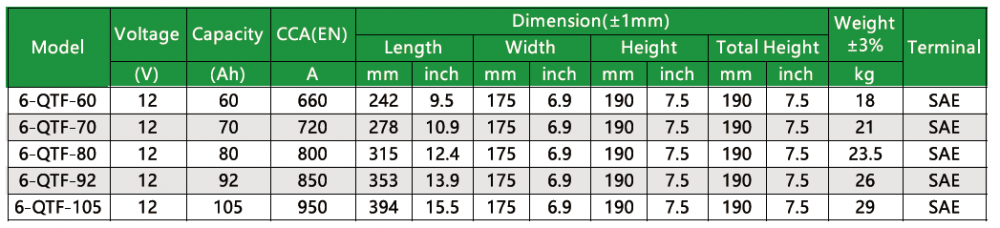

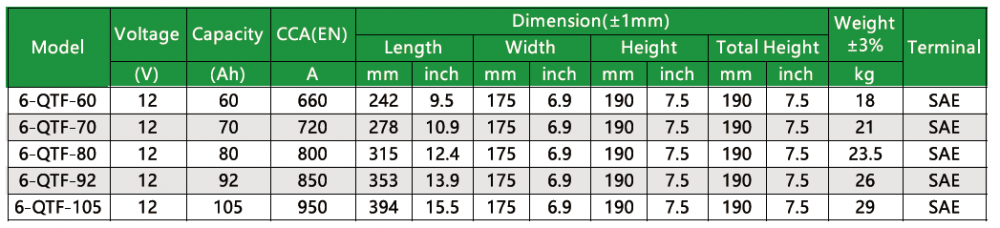

Specifications of OREMA QTF Series AGM Start-stop batteries:

Why choose OREMA as AGM start-stop battery provider?

The upgraded lead-carbon battery technology significantly improves battery life; By adding new active substances to the plate, the charging efficiency is significantly improved; At the same time, the low water loss ensures the long-lasting stability of the battery at high temperatures.OREMA QTF series AGM automotive batteries introduce innovative technology, showing excellent instantaneous high current release performance, and its continuous casting grid technology enhances the corrosion resistance of the grid; By improving the mechanical strength of the grid, the anti-shock performance of the battery is improved.

The OREMA QTF Series AGM Automotive Battery is known for its powerful starting power, low water loss and long service life, and is specially built for vehicles requiring basic electric support. While maintaining superior performance, it provides a higher price/performance ratio. OREMA QTF Series AGM automotive batteries are designed to simplify life and add value to your car by providing more affordable and responsive battery solutions from the consumer's perspective.

Choose OREMA car batteries, which are prized for their long-lasting performance. Quality products can withstand the test of time and user inspection.

car start-stop battery,Start-stop battery,AGM Start-stop batteries,AGM battery for car,12V AGM car batteries

OREMA POWER CO., LTD. , https://www.oremapower.com